คุณสมบัติของผลิตภัณฑ์นี้:

การออกแบบถ้วยปิด

การออกแบบถ้วยหมึกแบบปิด ช่วยประหยัดหมึกและเป็นมิตรต่อสิ่งแวดล้อม

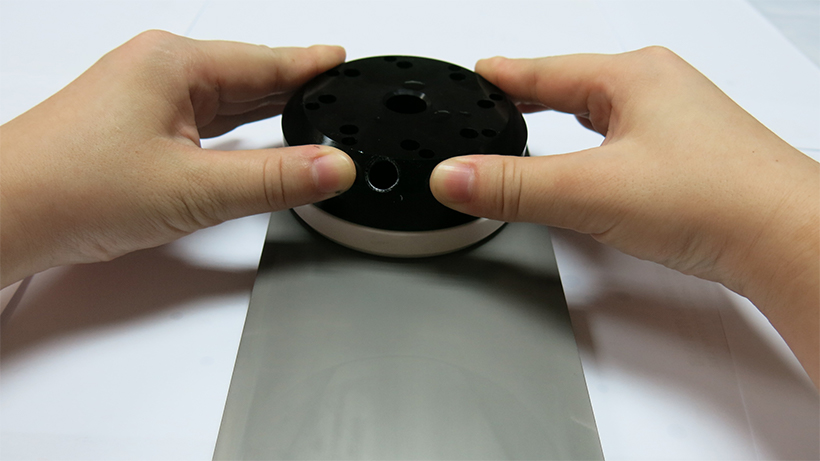

การเติมหมึกที่สะดวก

เติมหมึกได้ง่าย

ประกอบและถอดประกอบง่าย

ประกอบและถอดประกอบได้ง่าย มีความสามารถในการปรับตัวที่แข็งแกร่ง

ตัวถ้วยทนทานต่อการกัดกร่อน แข็งแรง และไม่เสียรูป

ตัวถ้วยที่ทนทานต่อการกัดกร่อน แข็งแรง และไม่เสียรูป สามารถทนต่อการสัมผัสกับหมึกต่างๆ เป็นเวลานาน หลีกเลี่ยงความเสียหายจากการกัดกร่อนทางเคมี

วินนีโอ การพิมพ์แพด ถ้วยหมึก

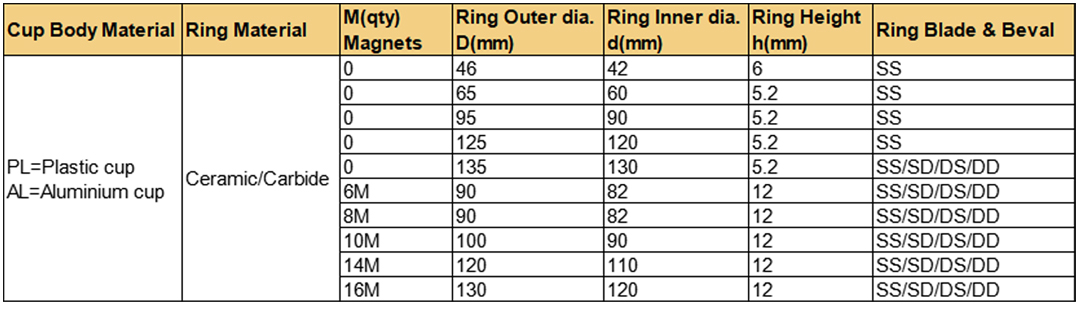

วินนีโอ ถ้วยหมึกพิมพ์แพด พารามิเตอร์

เราสามารถผลิตถ้วยและแหวนหมึกชนิดพิเศษตามคำสั่งซื้อของคุณได้

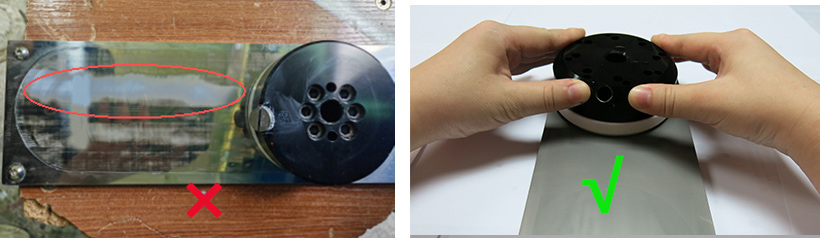

· ถ้วยน้ำมันมีการปิดผนึกที่ไม่ดีและมีแนวโน้มที่จะเกิดการรั่วไหลของน้ำมัน

· โครงสร้างของถ้วยใส่น้ำมันทำให้ทำความสะอาดได้ยาก

· แม่เหล็กในตัวของถ้วยน้ำมันเสียหายได้ง่ายและ

พลังแม่เหล็กลดลง

มาตรฐาน WINNEO ถ้วยหมึกพิมพ์แพด

เรามีถ้วยหมึกให้เลือกหลากหลายประเภทเพื่อให้เหมาะกับเครื่องพิมพ์แพดของคุณ

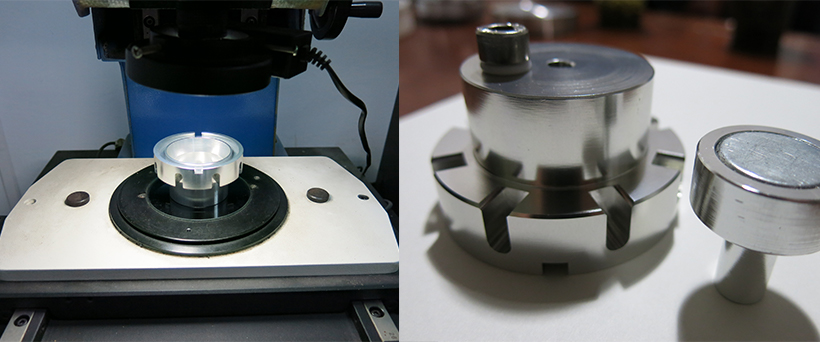

ถ้วยน้ำมันที่สมบูรณ์ประกอบด้วยชิ้นส่วนสี่ชิ้นดังต่อไปนี้

การตัดเฉือนที่แม่นยำช่วยให้ถ้วยหมึกถูกปิดผนึกอย่างดี

การทดสอบ QC ถ้วยหมึกพิมพ์แพด WINNEO

บรรจุภัณฑ์ที่ปลอดภัยของ WINNEO ช่วยให้มั่นใจได้ว่าถ้วยน้ำมันยังคงสภาพสมบูรณ์ระหว่างการขนส่ง

มาตรฐานหลังการขายของ WINNEO

ตอบสนองอย่างมีประสิทธิภาพภายใน 24 ชั่วโมง โดยมีเจ้าหน้าที่เฉพาะที่ได้รับมอบหมายเพื่อติดตามผล การสนับสนุนทางเทคนิคแบบออนไลน์แบบตัวต่อตัวตลอดอายุการใช้งาน

ลูกค้าแนะนำ

ถ้วยใส่หมึกพิมพ์แพด WINNEO ได้รับคำชื่นชมจากลูกค้าเป็นอย่างมาก

คำถามที่พบบ่อย

1.เลือกถ้วยหมึกอย่างไรให้เหมาะกับการใช้งาน?

ตรงกับรุ่นเครื่องพิมพ์แท่น; เลือกวัสดุตามคุณสมบัติของหมึก (ความหนืด การกัดกร่อน); ตรวจสอบว่าแหวนมีความคมและทนต่อการสึกหรอหรือไม่

2.วิธีที่ง่ายที่สุดในการทำความสะอาดถ้วยหมึกคืออะไร?

ทำความสะอาดหลังเลิกงานเพื่อป้องกันไม่ให้หมึกแห้งและแข็งตัว แช่ไว้ในตัวทำละลายเฉพาะ และถอดชิ้นส่วนรุ่นที่ถอดออกได้ก่อนเช็ด

3.หากถ้วยหมึกรั่วต้องทำอย่างไร?

ขั้นแรกให้ตรวจสอบแหวนซีล—เปลี่ยนใหม่หากเก่าหรือเสียหาย จากนั้นปรับความหนืดของหมึก (ถ้าหนาเกินไป อาจทำให้หมึกไหลล้นได้) สุดท้ายตรวจสอบว่าใบมีด/แหวนดอกกัดสึกหรอหรือไม่

4.ถ้าแม่เหล็กถ้วยหมึกไม่ยึดแน่นจะเกิดอะไรขึ้น?

ทำความสะอาดหมึกและสิ่งสกปรกออกจากพื้นผิวแม่เหล็ก เปลี่ยนแม่เหล็กโดยตรงหากแม่เหล็กอ่อนลง

5.ทำไมขูดหมึกไม่สะอาด?

ขั้นแรกให้ตรวจสอบใบมีดของหัวพิมพ์ (การสึกหรอ ช่องว่าง) จากนั้นตรวจสอบว่าแผ่นเหล็กแบนหรือมีรอยขีดข่วนหรือไม่ และสุดท้ายให้เพิ่มแรงกดถ้วยหมึก

เวลาทำงาน

รับข้อมูลของคุณได้ตลอด 24 ชม.

เวลาปักกิ่ง: วันจันทร์ - ศุกร์ 09.00-17.30 น.