เมื่อพูดถึง "การพิมพ์สกรีน" ภาพแรกที่นึกถึงมักจะเป็นเสื้อยืด ซึ่งก็ไม่ใช่เรื่องผิด แต่การจำกัดเครื่องพิมพ์สกรีนมาตรฐานไว้แค่การพิมพ์เสื้อผ้าก็เหมือนกับการบอกว่ารถยนต์มีไว้สำหรับขับไปซื้อของที่ร้านขายของชำเท่านั้น มันเป็นการมองข้ามศักยภาพที่แท้จริงของเทคโนโลยีนี้ในการผลิตเชิงอุตสาหกรรมและการตกแต่งผลิตภัณฑ์เชิงพาณิชย์ไปโดยสิ้นเชิง

คำว่า "มาตรฐาน" อาจทำให้เข้าใจผิดได้ มันไม่ได้หมายความว่า "พื้นฐาน" หรือ "จำกัด" แต่หมายถึงเครื่องมืออเนกประสงค์แบบใช้มือและกึ่งอัตโนมัติที่เป็นรากฐานของอุตสาหกรรม เครื่องจักรเหล่านี้เป็นเครื่องมือสารพัดประโยชน์อย่างแท้จริง พบได้ทั้งในโรงงานขนาดเล็กและในสายการผลิตขนาดใหญ่

แต่เมื่อคุณเตรียมตัวลงทุน คำถามพื้นฐานสองข้อก็ผุดขึ้นมาทันที: มันสามารถสร้างผลตอบแทนได้มากแค่ไหนกันแน่? และด้วยตัวเลือกมากมายนับพัน ฉันจะเลือกตัวเลือกที่เหมาะสมได้อย่างไร?

ส่วนที่ 1: เครื่องพิมพ์สกรีนมาตรฐานสามารถพิมพ์อะไรได้บ้าง? (คำตอบ: เกือบทุกอย่าง)

หลักการพื้นฐานของการพิมพ์สกรีนนั้นง่ายมาก: ไม้กวาดหมึกจะดันหมึกผ่านตาข่ายที่ตึง (สกรีน) ซึ่งมีภาพพิมพ์อยู่ ทำให้หมึกไปติดลงบนวัสดุรองรับ (ผลิตภัณฑ์ของคุณ)

นั่นหมายความว่าประสิทธิภาพของเครื่องจักรนั้นถูกจำกัดโดยหลักๆ สองสิ่ง ได้แก่ สูตรหมึกและตัวจับยึด (อุปกรณ์ยึดแบบกำหนดเองที่ใช้ยึดผลิตภัณฑ์ของคุณ)

1. โดยวัสดุรองรับ (Substrate)

เครื่องพิมพ์มาตรฐานสามารถรองรับวัสดุได้แทบทุกชนิด ตราบใดที่คุณเลือกใช้ระบบหมึกที่ถูกต้อง (เช่น หมึกตัวทำละลาย หมึกน้ำ หมึกยูวี ฯลฯ) เพื่อให้วัสดุยึดเกาะได้ดี

หมวดหมู่พื้นผิว | การใช้งานทั่วไปในอุตสาหกรรมและเชิงพาณิชย์ |

พลาสติก (แบบแข็งและแบบอ่อน) | กล่องหุ้มอุปกรณ์อิเล็กทรอนิกส์ (ABS, PC), ป้ายอะคริลิก (PMMA), ภาชนะโพลีโพรพีลีน (PP), แผงควบคุม PVC, สติกเกอร์ไวนิล |

โลหะ (เคลือบและไม่เคลือบ) | ป้ายชื่อทำจากอะลูมิเนียมชุบอะโนไดซ์ ตัวเครื่องเคลือบสีฝุ่น แผงด้านหน้าทำจากสแตนเลส ไม้บรรทัดโลหะ บรรจุภัณฑ์ทำจากดีบุก |

แก้วและเซรามิก | ขวดเครื่องดื่ม, ภาชนะบรรจุเครื่องสำอาง, เครื่องแก้วสำหรับห้องปฏิบัติการ, แก้วน้ำ, กระเบื้อง, กระจกรถยนต์ |

สิ่งทอและผ้า | เสื้อผ้า (แบบคลาสสิก), กระเป๋าผ้าแคนวาส, ป้ายผ้าไนลอน, กระเป๋าผ้าโพลีโพรพีลีนไม่ทอ, เสื้อกีฬา |

กระดาษและไม้ | การ์ดเชิญระดับไฮเอนด์, ภาพพิมพ์ศิลปะ, กล่องบรรจุภัณฑ์, ป้ายไม้, แผงวงจรพิมพ์ (PCB) |

ซิลิโคนและยาง | สายรัดข้อมือซิลิโคน ปุ่มกดแป้นพิมพ์ สินค้าส่งเสริมการขาย ซีลยางที่มีเครื่องหมาย |

2. โดยใช้เรขาคณิต (รูปทรง)

นี่คือจุดที่คนส่วนใหญ่เข้าใจผิดเกี่ยวกับเครื่องจักร "มาตรฐาน" พวกเขาคิดว่ามันใช้ได้เฉพาะกับสิ่งของแบนๆ เท่านั้น

ก) พื้นผิวเรียบ

นี่คือฟังก์ชัน "เริ่มต้น" ของเครื่อง ตั้งแต่โลโก้สีเดียวบนถุงผ้าไปจนถึงกราฟิกหลายชั้นที่ซับซ้อนบนป้ายโลหะ เครื่องพิมพ์แบบแท่นเรียบคือจุดเริ่มต้น

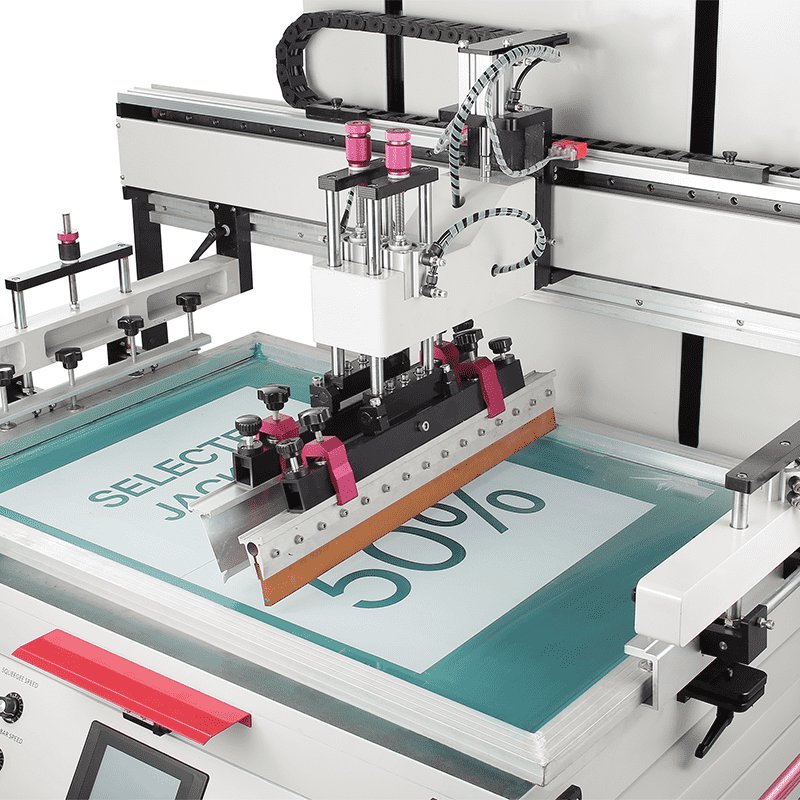

อย่างไรก็ตาม ในการใช้งานทางอุตสาหกรรม ความแม่นยำเป็นสิ่งสำคัญยิ่ง เมื่อพิมพ์ชิ้นส่วนอิเล็กทรอนิกส์ สวิตช์เมมเบรน หรือหน้าปัดเครื่องมือ การจัดเรียงชั้นสีแต่ละชั้น (การลงทะเบียน) ต้องสมบูรณ์แบบ นี่คือจุดที่เครื่องจักรประเภทนี้พัฒนาขึ้นมา เครื่องพิมพ์สกรีนแบนความแม่นยำสูงเครื่องพิมพ์นี้เหนือกว่าเครื่องพิมพ์เสื้อผ้า "มาตรฐาน" ทั่วไป มันถูกสร้างขึ้นบนโครงสร้างที่แข็งแรงทนทานและลดแรงสั่นสะเทือน และใช้ระบบการมองเห็นด้วยเครื่องจักร ระบบขับเคลื่อนเซอร์โวมอเตอร์ และการปรับด้วยไมโครมิเตอร์ เพื่อให้มั่นใจถึงความแม่นยำในการจัดตำแหน่ง ซึ่งเครื่องพิมพ์แบบแมนนวลธรรมดาไม่สามารถทำได้

ข) วัตถุทรงกระบอกและทรงกรวย

แล้วขวด ถ้วย หลอด และขวดบรรจุของเหลวขนาดเล็ก ล่ะ?

เครื่องจักรมาตรฐานสามารถดัดแปลงเพื่อใช้กับงานนี้ได้ โดยการเพิ่ม "อุปกรณ์เสริมทรงกระบอก" หรือ "เครื่องมือ" เข้าไป ฟังก์ชันการทำงานของเครื่องจักรก็จะเปลี่ยนไป เมื่อหน้าจอแบนเคลื่อนที่ อุปกรณ์จับยึดพิเศษจะหมุนขวดไปพร้อมกัน ทำให้ภาพจากหน้าจอแบน "กลิ้ง" ไปยังพื้นผิวโค้ง

สำหรับการผลิตในปริมาณมากที่ต้องพิมพ์กราฟิกในตำแหน่งเดียวกันบนขวดทุกขวด (เช่น จัดให้ตรงกับรอยตะเข็บหรือเครื่องหมายนูน) คุณจำเป็นต้องใช้ระบบที่ชาญฉลาดกว่า นี่คืองานเฉพาะของ... เครื่องพิมพ์สกรีนขวดทรงกลมสำหรับการวางตำแหน่งเคอร์เซอร์เครื่องนี้ใช้เซ็นเซอร์แสง ("เคอร์เซอร์") เพื่อค้นหาเครื่องหมายการลงทะเบียนที่มีอยู่แล้วบนผลิตภัณฑ์ เช่น รอยบากเล็กๆ ที่ก้นขวด หรือจุดพิมพ์ จากนั้นเครื่องจะหมุนขวดไปยังจุดเริ่มต้นที่แม่นยำนั้นโดยอัตโนมัติก่อนการพิมพ์ทุกครั้ง เพื่อให้มั่นใจได้ถึงความสม่ำเสมอที่สมบูรณ์แบบตั้งแต่ชิ้นแรกจนถึงชิ้นที่ 10,000

ส่วนที่ 2: ฉันจะเลือกได้อย่างไร?

เมื่อเรารู้ถึงความอเนกประสงค์ของเครื่องพิมพ์แล้ว เราจะเลือกเครื่องพิมพ์ที่เหมาะสมได้อย่างไร? ตลาดเต็มไปด้วยเครื่องพิมพ์หลายพันรุ่น ตั้งแต่เครื่องพิมพ์แบบตั้งโต๊ะใช้มือ ไปจนถึงสายการผลิตอัตโนมัติเต็มรูปแบบ

การเลือกเครื่องจักรผิดประเภทเป็นความผิดพลาดที่มีค่าใช้จ่ายสูง ต่อไปนี้คือปัจจัยสำคัญที่คุณต้องพิจารณาเพื่อสร้างกรอบการตัดสินใจ

1. ระดับของระบบอัตโนมัติ

นี่คือจุดตัดสินใจแรกของคุณ ซึ่งส่งผลโดยตรงต่อความเร็วในการผลิต ความสม่ำเสมอ และต้นทุนแรงงานของคุณ

ระดับการทำงานอัตโนมัติ | วิธีการทำงาน | ความเร็ว | ความสม่ำเสมอ | กรณีการใช้งานที่ดีที่สุด |

คู่มือ | พนักงานควบคุมเครื่องทำทุกอย่าง: ลดตะแกรงลง ดึงใบปาดน้ำ ยกตะแกรงขึ้น เปลี่ยนผลิตภัณฑ์ | ต่ำ | ระดับต่ำ (ขึ้นอยู่กับผู้ใช้งาน) | การสร้างต้นแบบ, งานอดิเรก, การสั่งซื้อแบบกำหนดเองจำนวนน้อย |

กึ่งอัตโนมัติ | ผู้ปฏิบัติงานทำการใส่/นำผลิตภัณฑ์ออกจากเครื่อง เครื่องจะทำการพิมพ์ (โดยใช้ไม้ปาดหมึก/แท่งกระจายหมึก) โดยอัตโนมัติ | ปานกลาง-สูง | สูง (ความดันและความเร็วคงที่) | ถือเป็น "มาตรฐานระดับทองคำ" สำหรับโรงงานอุตสาหกรรมส่วนใหญ่ |

ระบบอัตโนมัติเต็มรูปแบบ | ผลิตภัณฑ์จะถูกป้อนและส่งออกโดยอัตโนมัติ (เช่น ผ่านสายพานลำเลียงหรือแขนหุ่นยนต์) | สูงมาก | สูงมาก | การผลิตสินค้าชนิดเดียวในปริมาณมากโดยเฉพาะ |

2. การล่อลวง "สากล"

ธุรกิจใหม่จำนวนมากมองหาเครื่องพิมพ์เพียงเครื่องเดียวที่สามารถ "พิมพ์ได้ทุกอย่าง" ซึ่งนำมาสู่การเลือกใช้เครื่องพิมพ์สกรีนอเนกประสงค์

สิ่งสำคัญคือต้องเข้าใจความหมายของคำว่า "สากล" ในบริบทนี้ มันไม่ได้หมายถึงกล่องวิเศษที่ปรับตัวเข้ากับผลิตภัณฑ์ทุกชนิดได้โดยอัตโนมัติ แต่หมายถึงเครื่องจักรที่มีโครงสร้างแบบโมดูลาร์และปรับเปลี่ยนได้

A เครื่องพิมพ์สกรีนอเนกประสงค์ โดยทั่วไปแล้วจะเป็นฐานที่แข็งแรงทนทาน ช่วยให้คุณสามารถเปลี่ยนเครื่องมือและอุปกรณ์เสริมต่างๆ ได้อย่างรวดเร็ว ตัวอย่างเช่น:

ในวันจันทร์ คุณจะติดตั้งโต๊ะสุญญากาศเพื่อพิมพ์แผ่นโลหะเรียบ

ในวันอังคาร คุณจะเปลี่ยนไปใช้แม่พิมพ์ทรงกระบอกเพื่อพิมพ์ชิ้นงานลงบนขวดแก้ว

ในวันพุธ คุณจะติดตั้งแท่นพิมพ์หมวก

จุดเด่นของเครื่องจักรนี้คือความอเนกประสงค์ เหมาะอย่างยิ่งสำหรับโรงงานรับจ้างผลิต หรือธุรกิจที่มีผลิตภัณฑ์หลากหลายในปริมาณน้อยถึงปานกลาง ข้อเสียคือต้องใช้เวลาในการตั้งค่าเพื่อเปลี่ยนจากผลิตภัณฑ์ประเภทหนึ่งไปอีกประเภทหนึ่ง

3. ข้อมูลจำเพาะทางเทคนิคที่สำคัญ: รายการตรวจสอบก่อนซื้อของคุณ

เมื่อเปรียบเทียบราคา อย่ามองแค่ป้ายราคา ใช้รายการตรวจสอบนี้เพื่อเปรียบเทียบคุณสมบัติที่สำคัญต่อคุณภาพการพิมพ์และการใช้งานจริง

ข้อมูลจำเพาะหลัก | เหตุใดจึงสำคัญ (สิ่งที่ควรสอบถาม) |

การลงทะเบียนระดับไมโคร | นี่เป็นสิ่งที่ขาดไม่ได้สำหรับงานพิมพ์หลายสี หมายถึงปุ่มปรับที่ช่วยให้คุณปรับแต่งแกน X, Y และ Z ของหน้าจอได้อย่างละเอียด เพื่อให้ได้การจัดเรียงสีที่สมบูรณ์แบบ |

ถอดออกจากการสัมผัส (แบบสะบัดออก) | นี่คือช่องว่างแนวตั้งเล็กๆ (1-3 มม.) ระหว่างหน้าจอและผลิตภัณฑ์ ซึ่งจำเป็นอย่างยิ่งเพื่อให้ได้งานพิมพ์ที่คมชัด ระยะห่างนี้ตั้งค่า ปรับ และล็อคได้ง่ายหรือไม่? |

ระบบไม้ปาดน้ำและแท่งกระจายน้ำ | แรงดันสามารถปรับได้และสม่ำเสมอหรือไม่? มุมสามารถปรับได้หรือไม่? ในเครื่องจักรแบบกึ่งอัตโนมัติ แรงดันลม (นิวแมติก) ให้ความสม่ำเสมอมากกว่าระบบสปริงมาก |

โต๊ะดูดฝุ่น (สำหรับแท่นยกแบบเรียบ) | หากคุณกำลังพิมพ์บนวัสดุที่บางและเบา (กระดาษ ไวนิล พลาสติกบาง) โต๊ะสุญญากาศเป็นสิ่งจำเป็นอย่างยิ่ง มันจะช่วยยึดวัสดุให้เรียบและป้องกันไม่ให้วัสดุติดกับตะแกรงหลังจากพิมพ์เสร็จ |

คุณภาพการประกอบและโครงสร้าง | เครื่องจักรนี้สร้างจากเหล็กเชื่อมหนาหรืออลูมิเนียมน้ำหนักเบาที่ยึดด้วยน็อต? เครื่องจักรที่หนักกว่าและแข็งแรงกว่าจะช่วยลดการสั่นสะเทือนและรักษาความแม่นยำในการจัดตำแหน่งที่ความเร็วสูงได้ |

4. พิจารณาภาพรวมของกระบวนการทำงานทั้งหมด

สุดท้ายแล้ว คุณไม่ได้แค่ซื้อเครื่องพิมพ์ แต่คุณกำลังลงทุนในกระบวนการทำงาน งบประมาณของคุณต้องครอบคลุมขั้นตอนการทำงานทั้งหมด:

ขั้นตอนก่อนพิมพ์: คุณจำเป็นต้องใช้เครื่องฉายแสงคุณภาพสูงเพื่อสร้างแม่พิมพ์ คุณภาพของตะแกรง (จำนวนตาข่าย ความตึง) จะส่งผลโดยตรงต่อคุณภาพการพิมพ์ของคุณ

การอบแห้ง: หมึกจะไร้ประโยชน์หากไม่อบแห้งอย่างเหมาะสม นี่คือจุดบกพร่องที่พบบ่อยที่สุด คุณต้องเลือกเครื่องอบแห้งให้เหมาะสมกับหมึกและวัสดุที่ใช้พิมพ์ อาจเป็นเครื่องอบแห้งแบบสายพานลำเลียง (สำหรับสิ่งทอและหมึกตัวทำละลาย) หรือหลอดไฟ UV ความเข้มสูง (สำหรับหมึก UV อุตสาหกรรม)

การเลือกเครื่องพิมพ์สกรีน "มาตรฐาน" นั้นเป็นการพิจารณาถึงปริมาณการผลิต ความแม่นยำที่ต้องการ และความยืดหยุ่นของผลิตภัณฑ์ ควรระบุการใช้งานหลักของคุณให้ชัดเจน (แบบแบนหรือแบบทรงกระบอก) ประเมินความต้องการด้านระบบอัตโนมัติที่แท้จริง และตรวจสอบข้อกำหนดทางเทคนิคอย่างละเอียดถี่ถ้วน เช่น การจัดตำแหน่งที่แม่นยำสูงและการสัมผัสที่ไม่ตรงจุด เครื่องจักรที่เหมาะสมคือเครื่องที่สามารถควบคุมธุรกิจหลักของคุณ 80% ได้อย่างแม่นยำ ในขณะเดียวกันก็มีความยืดหยุ่นที่คุณต้องการสำหรับอนาคต

เวลาทำงาน

รับข้อมูลของคุณได้ตลอด 24 ชม.

เวลาปักกิ่ง: วันจันทร์ - ศุกร์ 09.00-17.30 น.